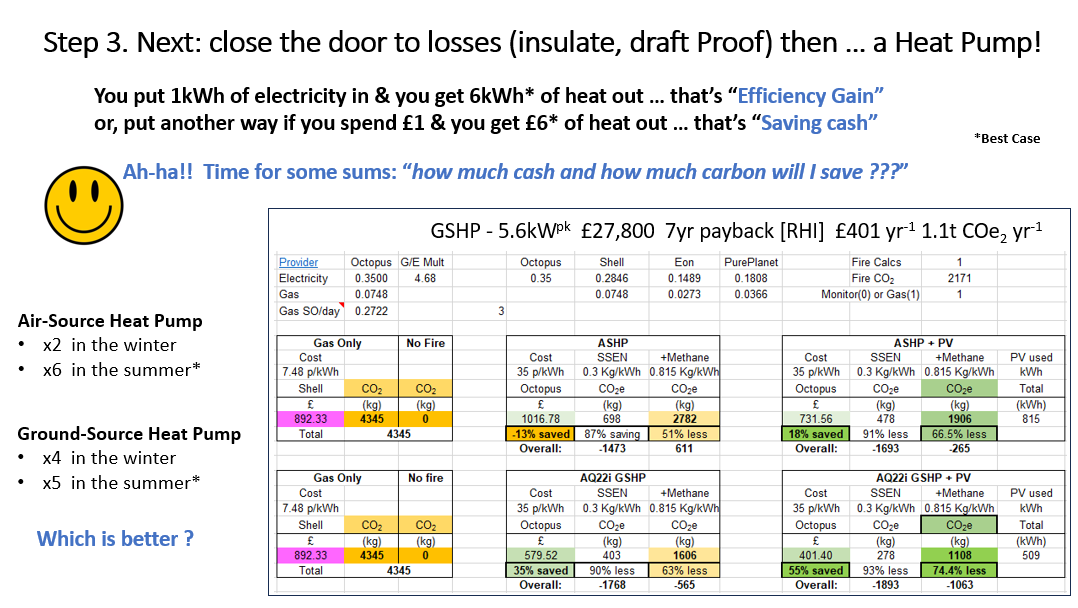

The next stage in Adrian’s Wood Lane retrofit decarbonisation journey was to look at heating and hot water. This followed a process of insulating and draft proofing the house. Adrian looked in detail at the carbon savings using his free Gas/electricity SMART meter data, free Weather data, free Heat Pump Datasheet data, a spreadsheet, and a set of scales for both Ground Source and Air Source Heat pumps.

Heat pumps vs Gas Combi Boilers

Heat pumps are one of the UK government’s preferred options for decarbonising household heating and hot water. Around 24 million households in the UK have some form of gas central heating, often in the form of a combi-boiler that provides domestic heating and hot water. This has been helped by the relatively low cost of gas per kWh compared with electricity. At the time Adrian was creating the comparison gas was 7.5p/kWh and Electricity around 35p/kWh.

Gas condensing combi boilers are advertised as being circa 90% efficient. But is that the case?

Adrian says-

Gas condensing combi boilers are now circa 90% efficient” … that’s what I thought, but not so! Gas boilers have a SCOP just like Heat Pumps do, because they too have a varying efficiency based on flow temperature, flow rate, DCH flow return temperature, servicing and demand usage characteristics. The [general headline] 90% Ƞ is the headline “top level” achievable efficiency. As well as CO2, they also emit CH4 and NOx; my calculations did not include realistic combi- efficiency for my boiler, nor CH4/NOx emissions, but I did include CH4 for my Grid Electricity (but not NOx). Overall, the point is that combi-boilers are not 90% efficient in the winter when you use them most.

Heat pumps however are between 200% and 600% efficient! The reason for this efficiency gain is the electricity powering the pump is being used to transfer heat from one source to another, rather than direct electric heating. This efficiency puts heat pumps on a par with gas combi boilers in terms of operational costs. With the addition of smart tariffs, time of use tariffs, and solar PV, heat pumps can be less expensive to run. Over time as the grid is decarbonised it is expected that electricity costs will reduce in comparison to gas and the greater efficiency will mean heat pumps become more cost effective to run than gas.

Air Source Heat Pumps

Air source heat pumps (ASHP) typically have a large fan to pass ambient air over a heat sink. They will work at temperatures as low as -20 degrees C. They are between 2x efficient in the winter to 5x efficient in the summer, though even in winter 3x efficiency can be achieved.

Ground Source Heat Pump

Ground Source Heat pumps (GSHP) transfer heat from underground, either through a borehole, or though shallower pipes laid underground across a larger area. With the borehole method the boreholes is lined with a steel 8” pipe down which two plastic pipes are dropped (with a “U” bend at the bottom); these connect to the GSHP unit – forward flow and return – and are filled with anti-freeze and meticulously filtered as this same fluid is what goes through the vapourisation nozzle in the heat pump to do the heat transfer.

Of the alternative shallow pipe laid underground method across a large area Adrian says…

…digging up soil is a really bad idea because i) it emits CO2 and ii) it destroys the eco-system that was living in the “soil” before we dug it up. This excellent video: Dr Matthew Shepherd: A fascinating introduction to life below ground [best of around 15 webinars I’ve watched on soil so far]

As the heat underground varies less than the air temperature they are more consistent, achieving x4 efficiency in winter and x5 in the summer.

At the time of writing both heat pumps attract the government Boiler Upgrade Scheme grant of £7500. For Air source heat pumps this can lower the cost of installation to be comparable, or sometimes less than a new gas combi boiler.

However the installation cost difference between the two is significant with Ground Source Heat Pumps costing many times more, the benefit being the greater operational efficiency.

Adrian opted for the Ground Source Heat Pump due to its greater efficiency and therefore carbon saving. He chose the borehole method of installation.

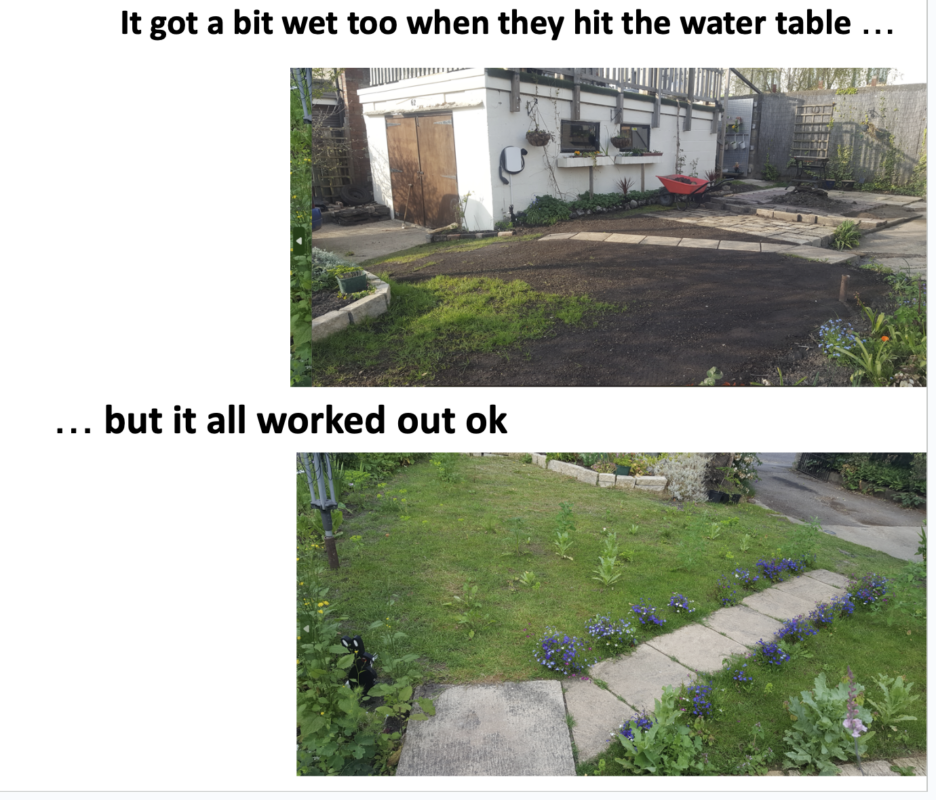

As you’ll see from the photographs Adrian chose the borehole method which was extremely messy and very stressful.

It got rather messy when the drill hit the water table, but… it all worked out OK in the end.

What about Hot water?

Adrian says…

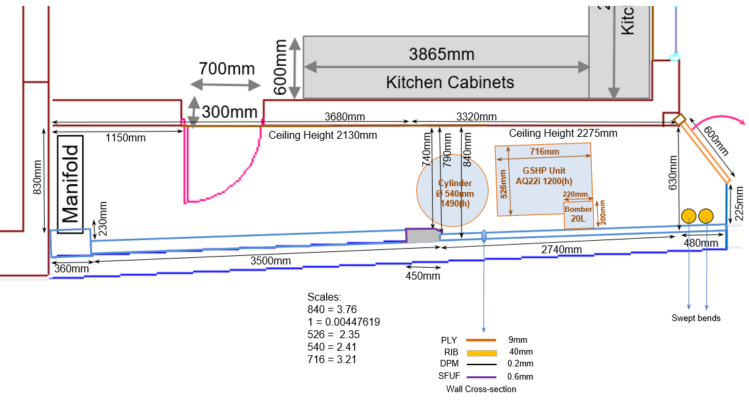

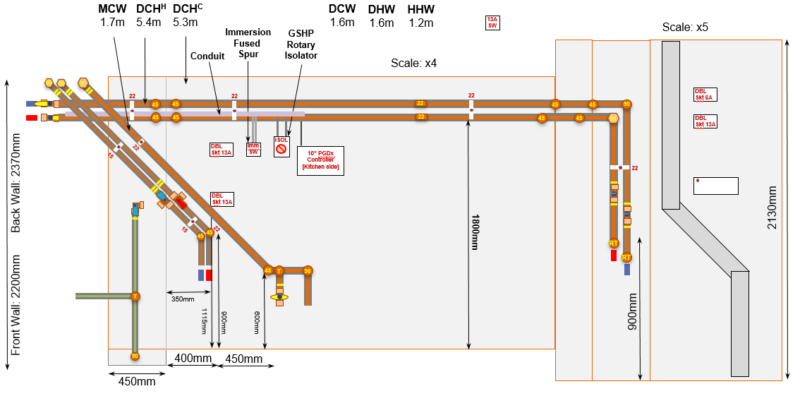

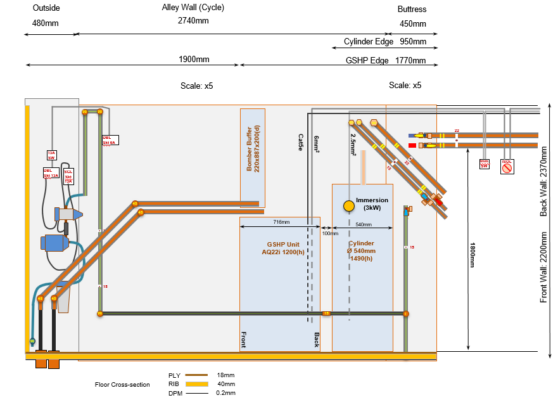

Previously I did not have a Direct Hot Water (DHW) cylinder (as I only had a combi) and if I’m honest I took 9 months agonising over where to put the GSHP & cylinder, eventually opting to compromise on indoor space I’d previously fought very hard to create because all the “inefficiency” of my system is heat (work is heat) and by putting the gubbins inside, all of that heat is captured into the house so from a house System Level the GSHP+associated plumbing is 100% energy efficient – it has no heat losses. Note that it’s extremely important to insulate everything that’s copper, everything that’s connected to anything copper and then to double or triple insulate the Buffer Tank and the Hot Water tank … (if at all possible). I did intend to put a combined GSHP/DHW Cylinder in as a system, but I was [basically] ripped off by the installation company and so have separate DHW cylinder and a slightly lower operating efficiency + bigger footprint than I had planned for & thought I had purchased. For an extra 60cm of GSHP unit height, a 180l DHW cylinder can be integrated into the GSHP unit. B******s! 😉

What about radiator sizing?

Adrian explains…

Technically – to achieve +23°C inside with -6°C outside – all of my radiators should be 3x or 4x times bigger than they are for my [then] EPC “D” house. I have retro-fit 18mm UFH on the entire ground floor sat on 6mm SF19 Superfoil insulation on concrete, on DPM, on soil. 1st Floor & attic have panel radiators in each room – all on 15mm copper pipe. However, after long discussions, it transpired that it’s not mandatory to upgrade the central heating to get an MCS certificate for the heat pump system. In general, (unless the installer does a “proper job” on you) you can try a winter or two ‘as is’ to determine which – if any – radiators need upgrading. I run my house fabric at around 17°C, with the living rooms heated to 19°C when we’re in them and bedrooms towards 18°C when we’re awake in them. My backup is an electric fan [I forgot to insulate my North-facing bathroom so I only de-frost it before a bath/shower with a 20min blast of fan heater] and if it goes to -20°C, I would use my wood burner as the 1660 house is actually designed for that – unlike modern houses; I also need to stop my internal chimney getting too wet after extensive rain. However, the approach to radiators being too small [when the DCH system is fully functional] is actually to insulate more. If they’re still too small, insulate more. And if they’re still too small, insulate more.

Was it all worth it?

Despite the installation mess and stress Adrian is extremely pleased with his Ground Source Heat Pump, estimating a 7 year payback on the investment, and a 1.1 tonnes of CO2 saved per year!

Adrian adds…

By watching the BBC weather forecast, I can ensure that my Direct Central Heating (DCH) is always heated up by the GSHP using my PV’s electricity (as it uses 1/5th the energy as an iBoost immersion controller) and if the sun isn’t going to shine, I schedule it to heat up during my Octopus EV early-morning charging period to save 70% on the cost of electricity. Similarly, I inject heat from the GSHP into the house during the EV-period, having turned it off at 9pm. 2 of these 3 cost-saving are not included in my cost-benefit analysis 😊 but they certainly show up in my ‘leccy bills ££££ … woop woop.

How did Adrian work out the Carbon savings?

The figures for my Combi gas usage were taken from my SMART meter hourly gas usage for each hour of each day of a full year from the date of calculation.

The figures for the external ambient temperature at my location for each hour over the same period were taken from Meteoblue dataset.

The figures for the carbon intensity at my location for every hour over the same period were taken from the CarbonIntensity data records & updated for CO2e /GWP10

As I was also using a woodburner, the kWh/day were recorded for each day it was used, having verified it’s output by weighing wood use/time burning for over a month. This usage was split into kW/hour, including the time the warmed chimney breast did heating after the fire was out. [I did not account for CO2e /GWP10 in these calcs as I was unaware at the time of the Supra-atmoshpheric dissolved CH4 content in the H2O of living wood]

The equivalent required Heat Pump output (heat) power for each hour in that previous year was determined by looking up the required electrical Heat Pump input power (kWh) from the COP data curves for every hour through that past year (for a range of Heat Pumps).

Having all of the above data for every hour of every day over the past complete year, I was then in a position to add up the various entities of interest over a year and make valid comparisons using real world data on a real house in which the way that heat/lifestyle/residence were held constant.

Inevitably engineering estimates need to be made in this process to allow reality to match best-estimated numbers, so generally I estimate at the conservative end of the scale (to increase cost or carbon).

My supplier did not give me access to the cloud data (which they originally promised) so monitoring/feedback of my estimates vs reality using real data has been disappointing but after much trying, I decided to go another way and record the GSHP I/P power using a power meter installed on the GSHP circuit in my Consumer Unit (which has been recording for just over a month), but there are a number of other benefits that I’d not factored in which have turned up, so I’d say the spreadsheet estimates are about correct on balance.

The Heat Pump does run more often than my gas combi boiler– this is actually a positive thing for a GSHP as it helps the house heat-draw out of the “battery of heat” deep in the ground to match the sub-surface heat replenishment rate into that battery, thereby allowing the GSHP to run at optimum efficiency for more time during a 24hr period. It’s a key point with Heat Pumps that the idea is to have a constant slow heat release into the “House System” to match the constant slow heat release of the “House System” out, into the ambient outside air … so having the GSHP running ‘all the time’ is by far the most efficient way to operate & I agree … that’s totally different from a Combi boiler [but it can make the house lovely and warm constantly 😊].

Note: “all the time” means a maximum of 1hr off and a maximum of 1.5hrs on …. & if the house doesn’t need the heat, the Off period gets dynamically longer & the On period gets dynamically shorter.

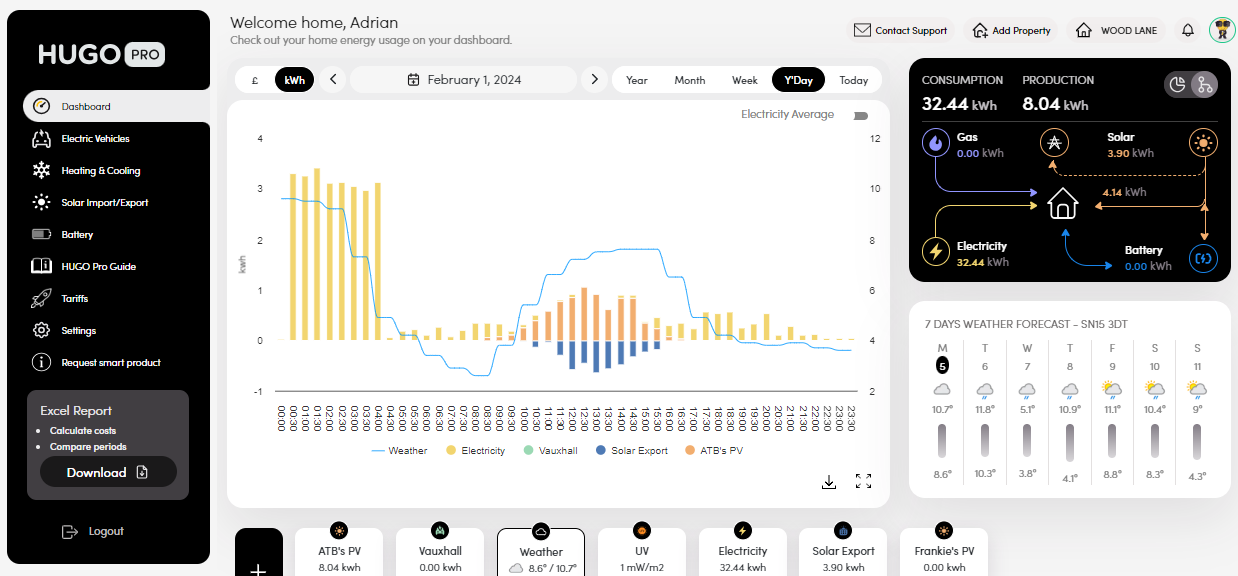

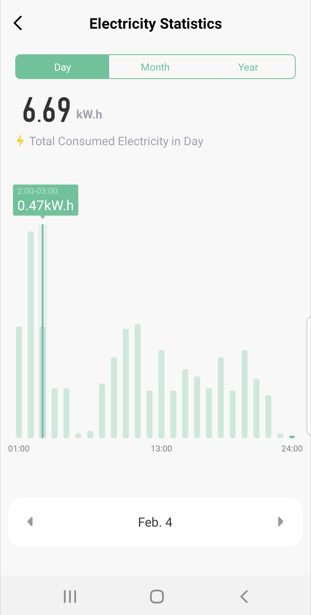

The all-green screenshot below shows GSHP power usage yesterday (no sun, but quite warm).

The Left Hand 3 bars are the GSHP heating up ~100Liters of water to 48C, the remainder are the GSHP running the DCH through the next 24hrs.

Because I have Octopus EV, I heat my DHW between 03:00 & 04:30 (at 9p/kWh) and/or I “over-heat” the central room in my house (via UFH) to avoid using the GSHP for the following few hours (at 32p/kWh)

The Hugo-Pro snip below (black/yellow) shows my EV taking on board 22.47kWh in eight 30-minute slots (with some household electrical activity on top of that – freezer + 80W background in this case)

It also shows that when the forecast is sunny, I can de-schedule DHW heating at night and schedule it instead to come from my fossil-fuel-free PV electricity (GSHP heating DHW from DHW 13:00 – 13:30 in this case).

The slide’s £401 annual saving does not include this sort of load-shifting btw (I’ve had my EV since 24-Mar-2023 & load-shifting like this into the low-cost EV charging period has saved £104 so far this year – I need OctoIntelligent !! ).